Specialization Autonomous Robotics

Stationary Robots

The first week of this engineering module focuses on stationary robots. After two days of general information about the operation of robots and robotic systems, students have three days of practical experience. Working in groups of three, they are given their own robot and learn all the steps required to start it up and move it around. A programming tablet allows them to immerse themselves in the practical experience of operating a three-dimensional robot. They will then be given the essential information about robot programming and gain an insight into working at expert level (using variables, arrays and structures and KLR, the KUKA Robot Language). Students learn how to translate coding into robot operations. All of our students have particularly enjoyed the creative experience of programming a game and seeing how their robot performs through their programming.

Autonomous Systems

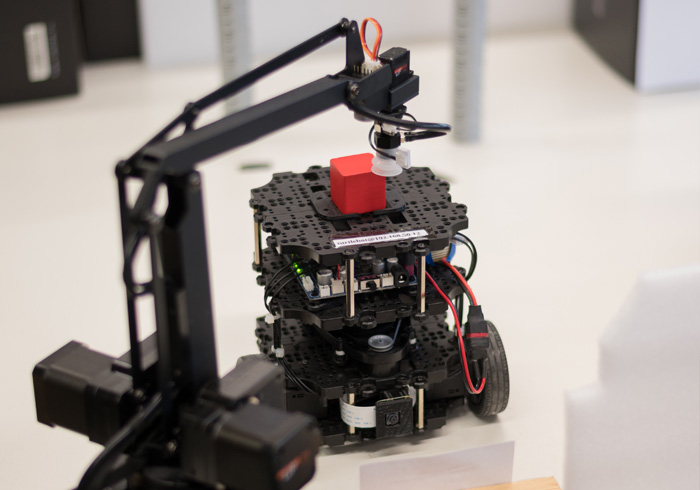

In the second week, students are introduced to autonomous systems by working hands-on with a set of model robots to create their own material handling system. They learn how to program robots using the Robot Operating System (ROS) and how autonomous systems can perceive their environment. Robots programmed in ROS are at the cutting edge of research and are becoming increasingly relevant in industrial applications. In these lectures, students get an insight into how autonomous robots can be used and how they can interact with other participants in the system. They learn how hardware and sensors behave in a real environment, while programming model conveyors, robot arms and freely navigating autonomous mobile robots.

In an increasingly competitive environment, products must meet equally high quality standards and innovations are disseminating ever faster. Participants of our Production and Operations Management program learn to encounter the challenge of striving for global optimum of the value creating chain while maintaining local responsibility for execution, reliability, sustainability, and quality.

Find out more